Examining how LlamaZOO fuses and visualizes LiDAR data across several different industries

Scalable and highly available cloud computing has reduced barriers to innovation, while powerful and increasingly inexpensive sensors are also used to gather data from every area of operations. Businesses in every industry are constantly incorporating technology to reduce downtime, save costs, identify new opportunities, and keep their people safe.

While businesses can collect more data, they often don’t know how to successfully integrate and manipulate it to create actionable insights. Even if data can be unlocked from within organizational silos and legacy systems, the sheer volume of data makes it difficult to analyze and visualize it.

In this blog post we examine how LlamaZOO fuses and visualizes LiDAR data in several different industries.

How Businesses Use LiDAR Data

LiDAR is a method for measuring distances by illuminating a target with laser light and measuring the reflection with a sensor. The technology is best known for its role in allowing self-driving cars to “see” their surroundings, but LiDAR is also used in everything from space travel to designing roads, bridges, and other infrastructure.

“LlamaZOO works with businesses across different industries to achieve their business goals by unlocking and visualizing their data.”

LiDAR Can Be Used to Create Detailed Visualizations to Achieve Business Goals

In order to gather this data, LiDAR instrumentation fires rapid pulses of laser light at a surface. A sensor on the instrument measures the amount of time it takes for each pulse to bounce back. With the right tools, the data then can be used to create, in great detail, a 3-dimensional visualization of the surrounding environment.

While self-driving cars are the best-known application of LiDAR, LlamaZOO has worked with businesses in several different industries to quickly unlock and visualize their data and achieve their business goals.

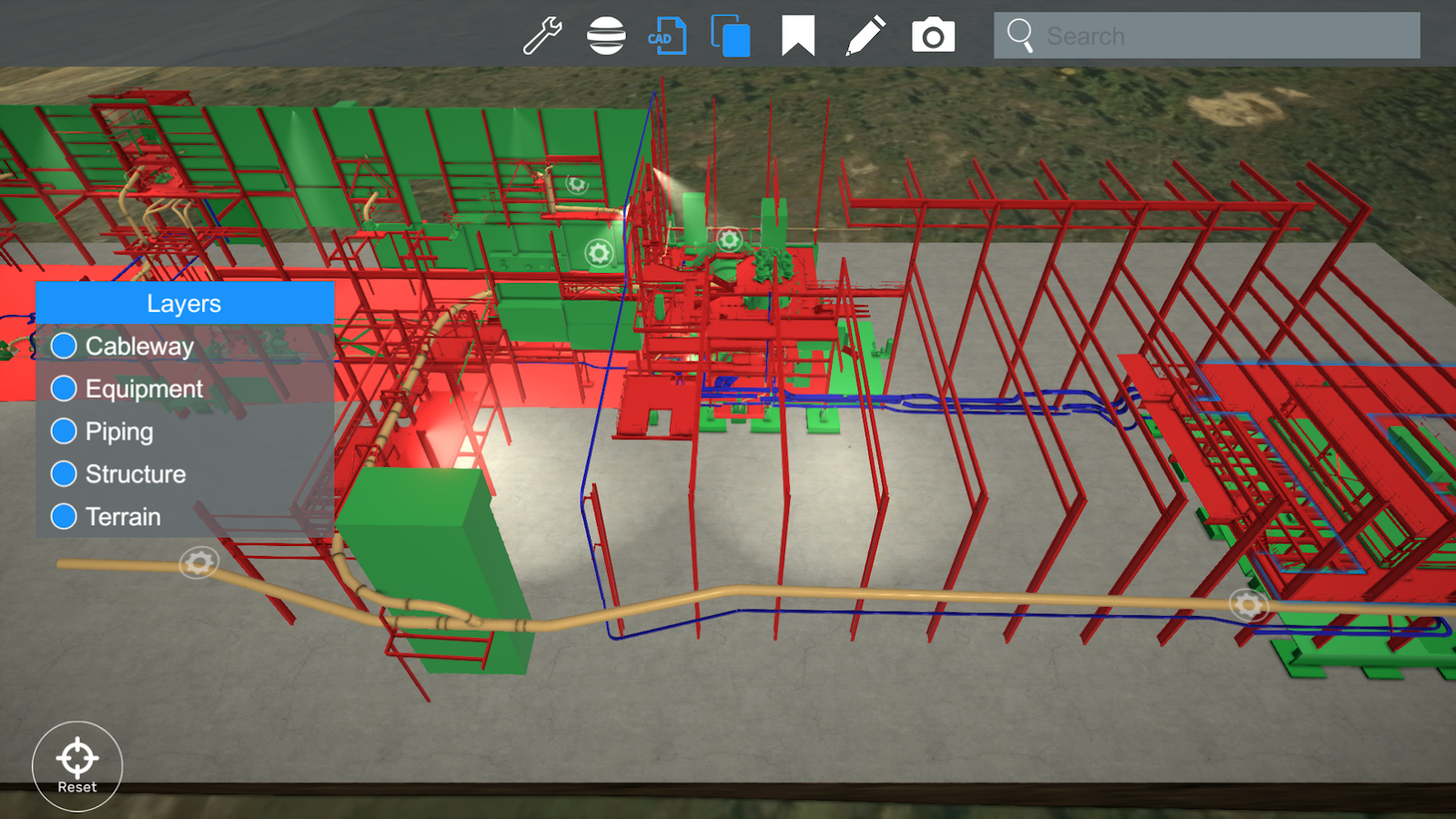

LiDAR in Manufacturing

One application of LiDAR data is to create a digital twin to compare the final “as-built” to the original “as-designed” of the CAD. Data is used to visualize the digital footprint of an entire manufacturing process, from design and development stages through to its production cycle.

The advantage of creating a digital twin of a factory includes achieving comparative analysis of as-build versus as-design for workflow optimization, reducing trial-and-error when designing a new production process or facility, and efficiently training workers before a plant even opens.

Digital twinning also enables remote inspection by SMEs (subject matter experts), saving time and keeping people safe.

Most recently, as a founding Digital Technology Supercluster member, LlamaZOO has contributed know-how to develop the Learning Factory Digital Twin, a proof-of-concept to apply digital twinning to the manufacturing process of aerospace components.

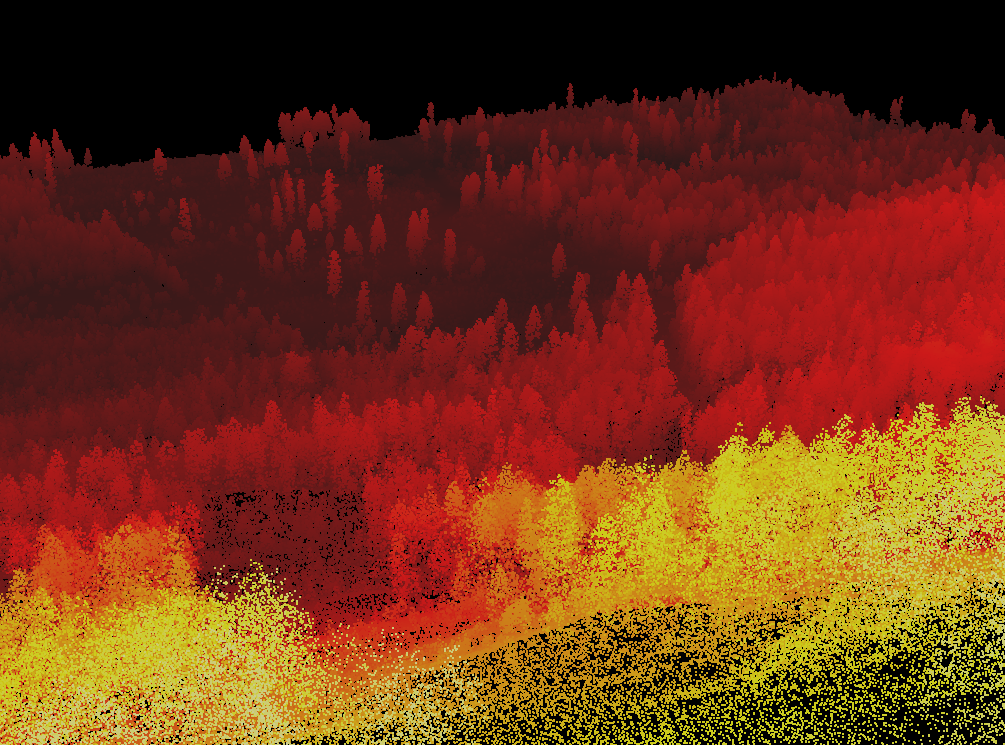

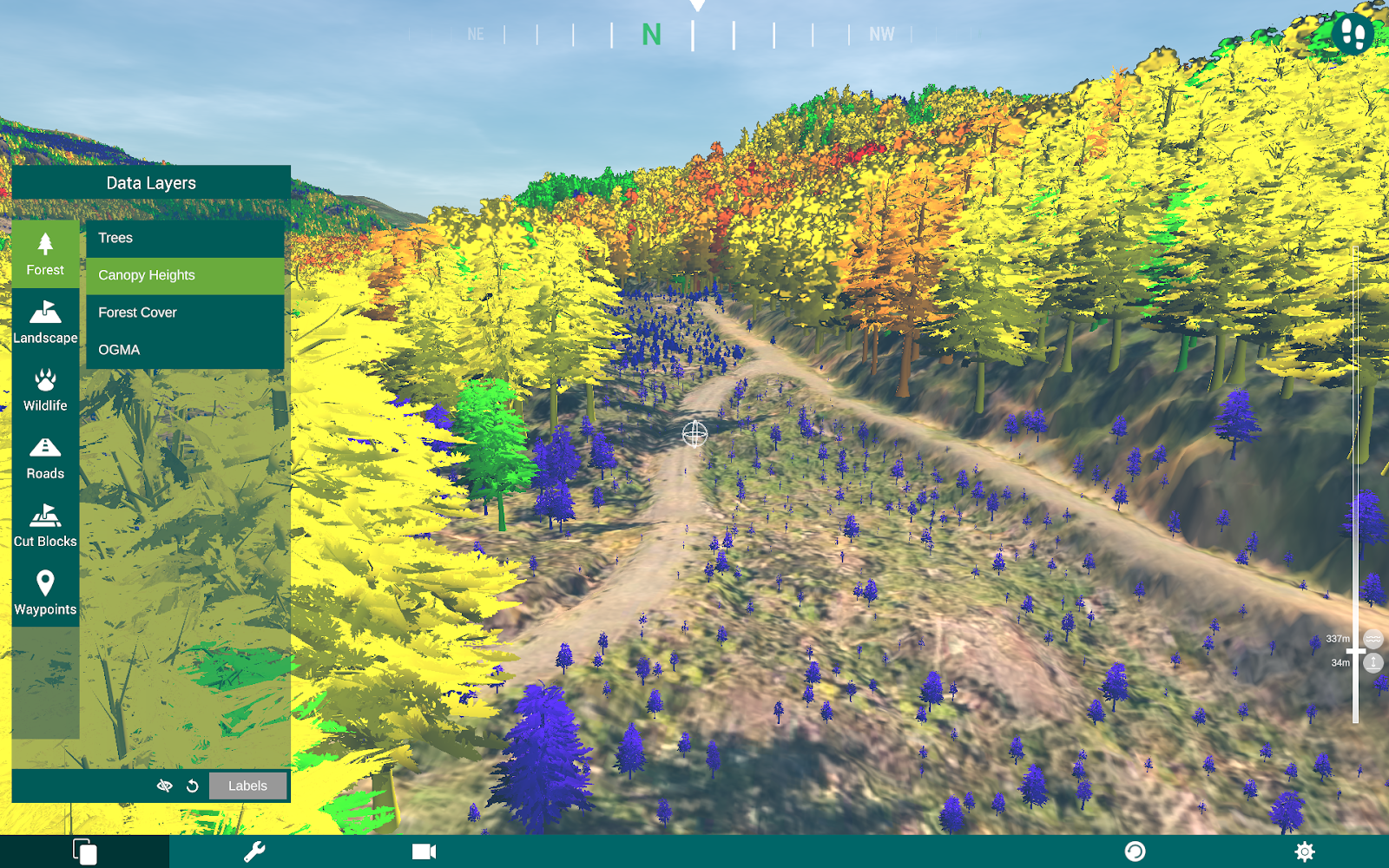

LiDAR in Forestry

In forestry, LiDAR provides precise, detailed information about forest canopy structure, as well as details about the ground underneath, such as terrain and slope. This data allows for cost-effective, large-scale surveys for harvest planning and road construction — one of the most cost intensive inputs in forestry.

LlamaZOO works with forest companies to liberate and visualize LiDAR and other data. This includes GIS, satellite, and aerial imagery of a proposed forestry license, into a 1:1 scale, common operating picture of the site which accelerates the harvest planning process and reduces costs.

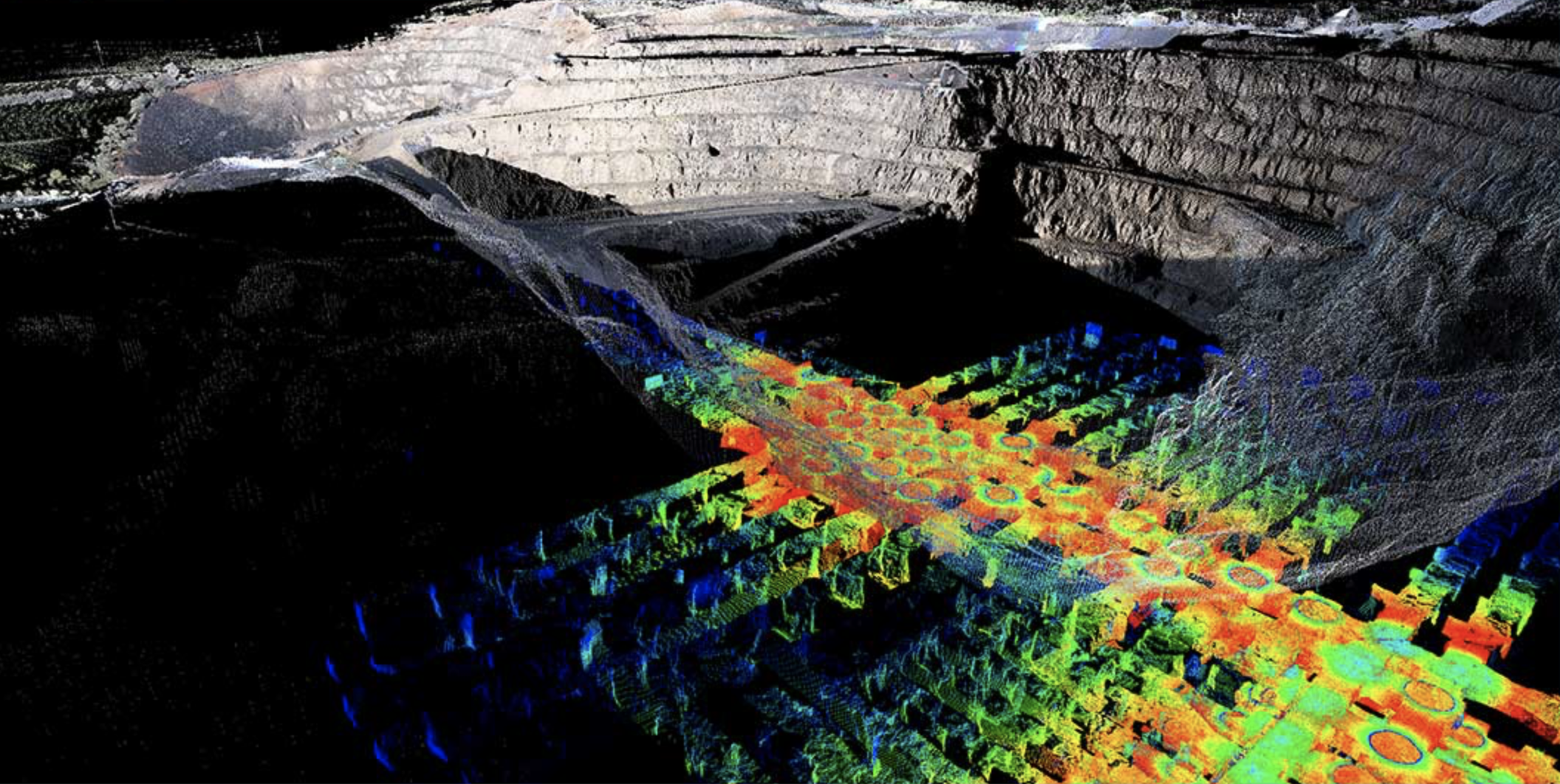

LiDAR in Mining

LiDAR data has many uses in mining. For example, LiDAR is used to identify and document important assets and locations used to plan and operate a mine site, including drill holes, facilities and infrastructure, and local flora and fauna and sensitive cultural sites. Once a mine is in operation, LiDAR is used for stockpile calculations — by scanning the stockpile, mine operators can accurately calculate the volume and thus the remaining inventory.

However, a major use of LiDAR data in mining is for tracking the movement of earthworks. LiDAR allows mining companies to accurately conduct surveys to track their progress versus plan. LiDAR is also used in mining to measure and track slope and wall grades, as well as dam stability and movement tracking to prevent catastrophic dam breaches.

This information is then synthesized and visualized into a 1:1 scale digital twin of a mine site, from exploration to reclamation.

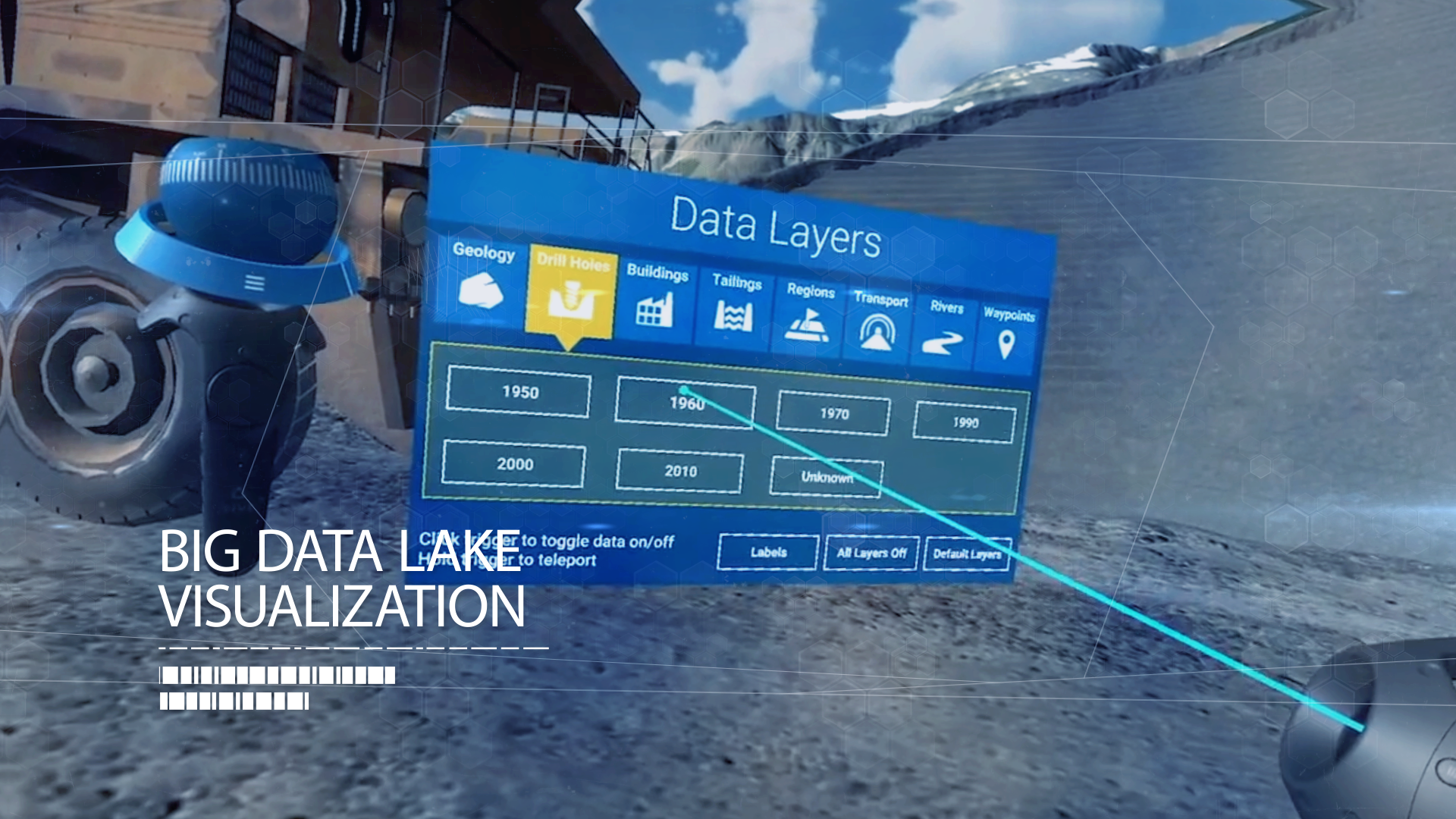

How LlamaZOO’s Spatial Business Intelligence Platform Solves the Problem of Liberating and Visualizing LiDAR Data

Businesses typically have three goals for the LiDAR data they generate and collect: they want to combine LiDAR data with other data sets, visualize the results and then better understand their operations. In theory, it should be straightforward for an internal team or vendor to unlock, fuse and visualize LiDAR and other data, but most businesses are confronted by significant challenges when attempting to do this.

Some businesses attempt to build in-house tools to extract, fuse and visualize LiDAR data. What would seem to be an easy task, instead requires hiring a project manager, building a team, spending months on developing a solution, and still not solving the problem of fusing LiDAR data with other data to create new, actionable insights. Another challenge when working with LiDAR and large data sets is that it is not easy to update the visualization with new data as conditions change and then share it.

To solve these problems, LlamaZOO’s Spatial Business Intelligence Platform liberates, integrates, and fuses LiDAR data with data from typically non-interoperable databases and legacy software across different organizational silos. As a purpose-built tool for analysis, our platform synthesizes and visualizes into a 1:1 scale digital twin of a manufacturing facility, cutblock or mine site, from planning to production and beyond.